Enterprises managing electricity, gas or even rail and road networks routinely control their infrastructure of overhead lines, transmission gas pipelines or aerial railways. This work aims to streamline the inspection process by using photo / video surveillance techniques to capture and store visual information to easily find the information you need as the basis for maintenance planning. Helipoland deals with the acquisition and smooth tracking of known visual features of industrial networks using a camera or other apparatus mounted on a helicopter.

Aerial patrols/inspections of power lines, railways, roads and pipelines

Aerial patrol is a cost-effective method of quickly covering wide areas and remote resources of power lines and pipelines or other critical infrastructure. We carry out aerial surveys with a customer observer on board or via camera systems and other devices, such as infrared cameras (infrared), corona cameras, lasers (LIDAR). In the case of companies that need information to manage their energy transmission systems or other infrastructure, we can cooperate in documenting proposed routes, recognizing potential threats or identifying elements and devices that require repair. Helicopter patrols provide quick access to area inspections because they are not limited by roads, impassable terrain or property lines, and are much faster and more advanced than drone inspections.

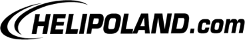

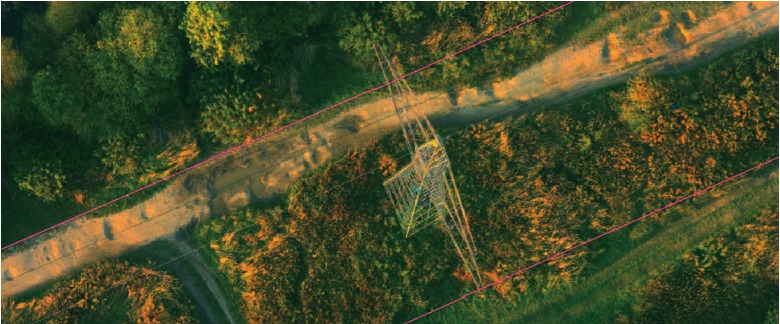

The most universal system is the container suspended from the helicopter, specially equipped with a set of at least 4 sensors. In addition to laser scanning, vertical and oblique images (forward and backward), there is thermography and corona imaging. The platform is most widely used in the energy sector, but subsequent projects (related to roads, railways, pipelines) show the advantages of this technology in infrastructure inventory along with the immediate environment. The timeliness, diversity and uniqueness of data collected simultaneously for a given section of infrastructure create great opportunities to use this information potential to maintain and maintain assets. Currently, such systems are already very advanced in terms of the quality of recording time-lapse photos with very high resolution and the level of integration with the laser and infrared camera through dedicated computers and software.

Infrared inspection services are designed to locate potential electrical problems and support media in eliminating failures in transmission, distribution and substation systems. The use of air thermographic cameras for infrared inspection provides the fastest and most accurate measurement method. We offer the most advanced and efficient infrared inspection services for power lines in the industry.

The history of patrol flights in the energy and gas industries is closely related to preventive measures. Initially, the focus was on ordinary visual inspection carried out by full-time employees who, as part of a walking tour of the network, made their observations in the form of map notes or tabular summaries. Gradually GPS receivers, tablets, cameras (including digital ones) and even vehicles allowing to move more efficiently in difficult terrain were introduced. Adverse weather conditions, which led to serious technical defects, and time pressure forced the use of helicopters. A patrol flight with an inspector on board, which indicated critical places, was carried out parallel to the line. Knowing the “own” line, he kept notes, additionally trying to document the object from various angles. The advantages of aircraft have been confirmed not only because of the speed of movement, but also the economy. The method turned out to be 10 to 30% cheaper compared to traditional scheduled inspections. At the same time, consideration was given to using better data storage media.

VHS cameras were introduced for use, which continuously recorded the image, allowing not only to analyze the line, columns, but also the environment, which is important due to the threat arising from the proximity of trees. In connection with the development of recording techniques and data carriers, flights were started over the lines at a fairly low ceiling (up to 15 m above the line), recording the view from above through adapted viewfinders or outriggers outside the cabin. Ultimately, lightweight vertical and oblique time frame recording systems mounted under the helicopter worked best. They were usually devices with a matrix size of several megapixels resembling primitive industrial cameras in protective housings permanently attached to the helicopter chassis. With time, more and more attention was paid not only to the resolution, but also to the quality of oblique images, which due to the information potential are very valuable during chamber analyzes of the assessment of the general condition of the power line, including identification of damage to insulators and their equipment, location of damaged glass cells or degree of damage to porcelain insulators, including chain breaking, etc. In parallel with the recording of vertical and oblique images, the network geometry is inventoried. In addition to the wires, the scanner accurately samples (measures) the environment, including terrain that dynamically changes below the line. A properly collected data set allows you to analyze the thermal load of the line. It turns out, therefore, that modernization does not have to include extending the line, i.e. strictly construction works. It is enough to specify the maximum current under given conditions that will not exceed the permissible values in accordance with the standards. Appropriate software then allows you to measure the distance between modeled line conductors and crossed objects whose three-dimensional position in space has been recorded by a laser scanner with an accuracy of several centimeters.

Technical maintenance of power networks

Aerial patrols/inspections of pipelines / gas pipes

Pipeline infrastructure is extremely important in the everyday functions of our country. Currently, there are over one hundred thousand kilometers of gas transmission pipelines in the country subject to cyclical aerial inspections. Due to the increase in energy demand, the focus has been on strict pipeline regulations, and emphasis on pipeline inspections ensures that no leaks or failures occur. These programs combine structural state assessment with regular verification of leakage testing to further reduce the risk of catastrophic failure.

However, these evaluation efforts require man-hours and pipeline inspection is a very labor-intensive process. Inspections include a thorough review, identification and mitigation of anomalies. With Helipoland helicopters, we can help in various aspects of the inspection process.

Given that the loss of pipeline products as a result of unidentified leaks results in annual losses of profits and safety risk, pipeline air inspections are not only a safety issue, but also an important tool to prevent losses. The ability to measure greenhouse gases in the environment is also becoming more and more important as the world fights climate change.

Helicopter pipeline inspections are the fastest and most reliable way to monitor oil and gas pipelines. Advanced imaging technology allows experts to respond quickly and efficiently to leaks without road restrictions, impenetrable terrain or property lines to minimize the environmental impact of pipeline anomalies and provide adequate consumer service.

Traditional pipeline measurements and assessments are extremely expensive and ineffective, which may prevent the pipeline company from carrying out appropriate inspections. Expenses additionally increase the contract company’s general costs, which can negatively affect the company’s profitability, especially in the highly competitive industrial energy management market. Helicopter inspections address these problems by providing quick, convenient and cost-effective inspection options. All helicopter classes are available at a glance, helping even in the most complex situations.

Aerial patrols/inspections of railways and roads

Inspection flights on the rail or road network are usually carried out on an ad hoc basis in the face of pre-identified operational problems or more frequently in construction work. They allow you to quickly identify problems by recording video footage independently by the camera operator in a team with a helicopter pilot or with the assistance of a qualified employee of the rail or road industry. These types of rail or road infrastructure inspections are also carried out for the purposes of ongoing documentation of ongoing investments. The recordings are then used for engineering or legal purposes for own or investor needs.