No helicopter is so tolerant of neglect as to be safe in the absence of an effective inspection and maintenance program. The processes affecting the deterioration of the technical condition of helicopters with age are related, among others, to the condition of materials (e.g. fatigue, wear and corrosion) or chance failures (e.g. broken component, excessive design loads).

Maintenance is an activity necessary to maintain or restore the integrity and performance of a helicopter and the process of ensuring that its systems continues to perform intended function at the level of reliability and safety designed.

We provide the highest quality standards in maintenance, necessary to keep your machine in the air. We invite you to talk to our experienced technical team who will explain how we will provide service for your helicopter.

Maintaining the proper technical condition of a helicopter can be defined in many ways, such as activities required to restore or maintain a component in a serviceable condition, including maintenance, repair, modification, overhaul, inspection and condition determination. The responsibilities of Aviation Technology Departments of aviation authorities include handling matters related to the airworthiness and supervision over the continuing airworthiness of aircraft, engines, propellers, components (products) and the design, production and maintenance of aircraft and aviation products, as well as marking and aircraft registration and environmental protection related to the operation of aircraft, in terms of noise and exhaust emissions.

Helicopter technical activities include:

Airworthiness management in the Continuous Airworthiness Management Organization (CAMO)

CAMO’s competences include, among others: creating and updating Technical Maintenance Programs, development and approval of Test and Control Flight Programs, supervision and commissioning of repairs, overhauls and any unplanned service activities, supervision and analysis of airworthiness directives (AD ), service documentation (SB / SL / SI) and safety bulletins (SAIB), monitoring of components with limited service life and requiring periodic repairs, creating and developing the Minimum Equipment List (MEL), organizing approvals of any modifications (STC), issuing and extending the certificate airworthiness review (ARC). Entrusting the management of your aircraft means that CAMO takes responsibility for maintaining the highest safety standards and completing all formalities related to the operation of the aircraft.

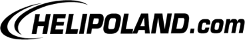

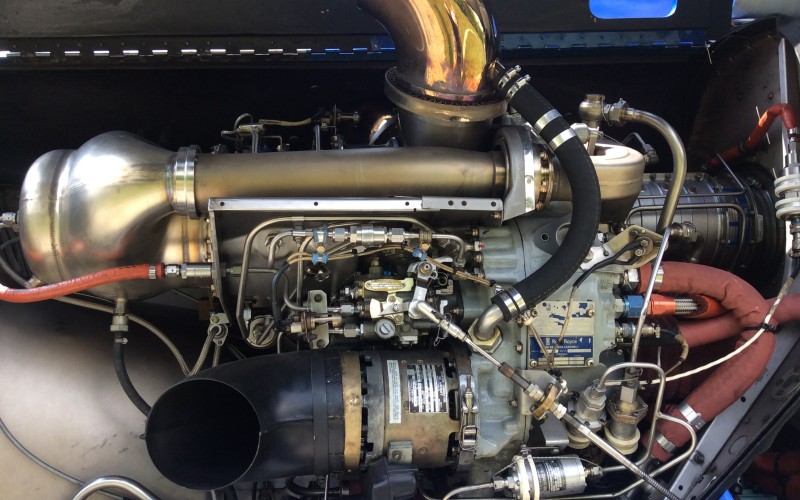

Periodic and ad hoc maintenance by an Approved Maintenance Organization (AMO)

In order to create conditions for the proper operation of the purchased helicopter, based on the standards and requirements of the manufacturer and current aviation regulations, our company provides professional technical service during the performance of all maintenance activities and all works, both during the limited warranty period provided by the manufacturer and after it. We provide helicopter service by helicopter mechanics with many years of experience, additionally trained in the manufacturer’s factory, eg Robinson Helicopter Company in Los Angeles. Please be advised that we have an adequate stock of original spare parts, which can be replaced if necessary, and we cooperate with a number of world-renowned aviation companies, which are always helpful to us in justified cases. If necessary, appropriate original parts are delivered directly to the manufacturer.

Ongoing inspections conducted by pilots during flights (pilot preflight, postflight inspections)

Pre-flight external inspection of the helicopter is part of the acceptance for flight by the pilot-in-command and must be formally recorded in the aircraft’s technical log prior to each flight. They are primarily a general visual inspection of those aspects of the aircraft airworthiness that can thus be fully or partially verified. The external inspection should only be performed after the aircraft technical logbook and other on-board documentation have been properly checked by the pilot-in-command of the aircraft.

The basis for an effective external check is knowledge of the aircraft. Damages from a previous flight which were disregarded during the external inspection may be assigned to a new crew that failed or caused the external inspection! Knowledge, attention to detail and vigilance will prevent important issues from being overlooked.

The recommended content of the external inspection will be detailed in the aircraft operating manual in the form of an extended checklist, and the comments which are general, highly selective and usually not sequenced. External inspections that are carried out at night require the possession and use of a flashlight with effective brightness; The illumination of the apron alone is not enough.